Temperature (outdoor, indoor, of technical devices, etc.) can be measured by a wide range of CFox and RFox modules, or by separate temperature sensors connected to the analogue inputs of CFox, RFox and Foxtrot modules. Tab. 7 gives a brief overview of the most widely used temperature measurements and the recommended sensors; Tab. 8 shows the ranges of analogue inputs of individual CFox and RFox modules.

Basic types of temperature sensors (a brief overview)

The Pt1000 – a platinum resistance temperature sensor with the R0 = 1,000 Ω basic resistance at 0 °C. There are also produced sensors with a different resistance at 0 °C: the Pt100 (R0 = 100 Ω), Pt500 and others.

The quality of the platinum sensor is high, is features long-term temperature stability, a disadvantage is somewhat lower sensitivity (lower Tk) and a higher price.

Tk = 3,850 is the standard temperature coefficient of resistance in platinum sensors.

There is also used the so-called "American version" with Tk = 3910.

The parameters are defined by the EN 60751 standard: Industrial platinum resistance thermometers and platinum temperature sensors.

Tab. 1. Tolerance classes for platinum resistance thermometers and platinum temperature sensors

|

The tolerance class |

B |

A |

|

Basic tolerance range |

± 0.3 + 0.005. l t l °C |

± 0.15 + 0.002. l t l °C |

|

The temperature range |

-200 ÷ +850 °C |

-200 ÷ +650 °C |

The most common class for standard applications is class B.

The temperature coefficient of resistance defines the relation between the resistance and the temperature. It is defined in several ways, e.g. the coefficient of Pt1000 sensors, the European implementation:

The temperature coefficient of resistance α = 3.85 x 10–3[ °C-1]

or Tk = 3,850 ppm/ °C (correctly 3851, after a refinement of the value in the A2 appendix of the ČSN EN 60751 standard),

or W100 = 1.385 (the ratio of resistance R100 at 100 °C and resistance R0 at 0 °C).

Ni1000 - a nickel resistance temperature sensor with the basic resistance at 0 °C R0=1000 Ω. A standard resistance sensor, in comparison with Pt sensors it has a smaller temperature measuring range, good stability, is very popular in measurement and control applications.

By default, nickel sensors are supplied with the temperature coefficient of resistance at Tk = 6,180 (W100 = 1.618) or Tk = 5,000 ( W100 = 1.500).

Tab. 2. Tolerance classes for nickel resistance thermometers

|

The tolerance class |

B |

|

Basic tolerance range |

± 0.4 + 0.007. l t l °C |

|

The temperature range |

-50 ÷ +250 °C |

NTC 12k - thermistors with a negative temperature coefficient of resistance. Inexpensive sensors, with a smaller temperature range and worse precision. They have a very nonlinear characteristic.

NTC 12k – a sensor with a 12k resistance at 25 °C. There are produced a number of NTC sensors with various resistance values at 25 °C: 5k, 10k, 15k, and others.

Tab. 3. Tolerance for thermistors with a negative temeprature ceofficient

|

Maximum tolerance of resistance at 25 °C, R25 |

typically ± 3 % |

|

The temperature range |

- 45 ÷ + 125 °C |

KTY 81-121 - a silicon temperature sensor with a positive temperature coefficient. A cheap resistance sensor with lower accuracy (the basic error is about ± 2 °C at ambient temperature).

Tab. 4. Detail information about the silicon temperature sensors

|

Nominal resistance R25 |

980 ÷ 1000 Ω |

|

The temperature range |

- 55 ÷ + 150 °C |

TC - a thermocouple, a thermoelectric temperature sensor.

Thermocouples are mainly used for measuring very high temperatures, up to 2,300 °C; the sensors have poorer stability over time and very low sensitivity. .

Thermoelectric sensors are based on the Seebeck effect (converting thermal energy into electricity). A thermocouple consists of two wires of different metals with a conductive connection at each end. If the temperature tm of the measuring junction differs from the temperature of the t0 reference junction, small thermoelectric voltage occurs (only several dozens of mV). The reference junction should be constant at the temperature of t0 in order for the sensor to work properly. Alternatively, the impact of the thermoelectric voltage of this junction should be compensated (using the so-called cold junction compensation, CJC). In order to connect the sensor with the system analogue input, compensation or thermocouple wiring is required.

Thermocouple wiring is made of the same material as the thermocouple itself. That is the reason why there are also types J, K, etc. Owing to this, no new thermocouples occur in other joints (e.g.on the terminals between the thermocouple and the subsequent cable). If we used an ordinary wire, the combination of the two different materials would result in creating another thermocouple, which would generate voltage in relation to the temperature of this joint. This voltage would be added to the voltage of the thermocouple itself, rendering the measured values worthless.

Compensation wiring is a cheaper substitution of thermocouple cables. The material is not identical with that of the thermocouple, and the compensation wiring maintains the same parameters as thermocouple cables, but only up to 200 °C (rarely to 260 °C).

The specific type of thermocouple and the mechanical design of the sensor must be addressed with respect to each specific application. This text has been compiled with the help of information thermoprozess.cz, where you will also find a specific selection of thermocouple sensors.

Tab. 5. Basic properties of thermocouples (the selection according to the module C-IT-0200I):

|

Type |

Range |

Usage |

|---|---|---|

|

B |

250 to 1,820 °C |

Suitable for extremely high temperatures |

|

J |

-200 to 1,200 °C |

Suitable for oxidation, reducing, inert atmosphere and vacuum. |

|

K |

-200 to 1,370 °C |

Suitable for oxidation, reduction and inert atmosphere, not suitable for vacuum. |

|

N |

-200 to 1,300 °C |

Suitable for frequent and great variations in temperature; it does not respond to the neutron flux (suitable for the nuclear industry). |

|

R |

-50 to 1,760 °C |

Suitable in high temperatures, resistance against corrosion and oxidation. |

|

S |

-50 to 1,760 °C |

-the same- |

|

T |

-200 to 350 °C |

The most suitable sensor for measuring low temperature, it can be used in vacuum, oxidizing and reducing atmosphere. |

Tab. 6. A summary table of the relation between the resistance of sensors and the temperature

|

Type of sensor |

Pt1000 |

Ni1000 |

Ni1000 |

NTC 12k |

KTY 81-121 |

|

Tk |

3850 |

6180 |

5000 |

- |

- |

|

°C |

Ω |

Ω |

Ω |

kΩ |

Ω |

|

-20 |

921,6 |

893 |

913,5 |

98,93 |

677 |

|

-10 |

960,9 |

945,8 |

956,2 |

58,88 |

740 |

|

0 |

1000 |

1000 |

1000 |

36,13 |

807 |

|

10 |

1039 |

1055,5 |

1044,8 |

22,8 |

877 |

|

20 |

1077,9 |

1112,4 |

1090,7 |

14,77 |

951 |

|

25 |

1097,3 |

1141,3 |

1114 |

12 |

990 |

|

30 |

1116,7 |

1170,6 |

1137,6 |

9,8 |

1029 |

|

50 |

1194 |

1291,1 |

1235 |

4,6 |

1196 |

|

100 |

1385,1 |

1617,8 |

1500 |

0,95 |

1679 |

|

150 |

1573,3 |

1986,6 |

1799,3 |

- |

2189 |

|

250 |

1941 |

2896,4 |

- |

- |

- |

Tab. 7. Classification of temperature sensors according to the measuring technology

|

Measuring |

Module on CIB |

Independent sensor |

RFox module |

Note |

|||

|

Interior temperature |

TXN 133 20 |

- |

The wall-mounted sensor, on customer's request |

||||

|

TXN 133 19.01 |

TXN 134 01.01 |

R-IT-0100R-Time |

The wall-mounted sensor, the ABB Time design |

||||

|

TXN 133 19.xx |

TXN 134 01.xx |

- |

ABB design sensor (except for the Time), it must be specified |

||||

|

Outdoor temperature |

C-IT-0100H-P |

|

Sensor on the facade |

||||

|

The floor temperature |

|

|

Sensor for underfloor heating regulation |

||||

|

Temperature of the solar heating circuit medium |

|

|

The cable temperature sensor mounted on a pipe in the circuit |

||||

|

Water temperature in the tank |

|

|

The cable sensor inserted in the tank immersion sleeve |

||||

|

Water temperature in the piping |

C-IT-0100H-P |

|

Contact sensor, heating water and utility water, solar systems |

||||

|

C-IT-0100H-P |

R-IT-0100H-A |

Sensor with an immersion sleeve (installed inside a pipe) |

|||||

|

Air temperature in the duct |

C-IT-0100H-P |

|

An internal pipe sensor, HVAC regulation, the length of the stem must be specified |

||||

|

Water temperature in the swimming pool |

C-IT-0100H-P |

|

A sensor in the immersion sleeve in the piping, the length of the stem must be specified |

||||

|

Boiler flue gas temperature |

C-IT-0200I, TXN 133 09 + thermocouple sensor |

|

Thermocouple sensor measured by the C-IT-0200I module |

||||

Notes:

-

For the ABB Tango design, a different variant of the sensor order no. should be used: TXN 134 02.01 (the standard version in white).

For an overview of modules and types of connectable temperature (and other analogue values) sensors, see the Tab. 8.

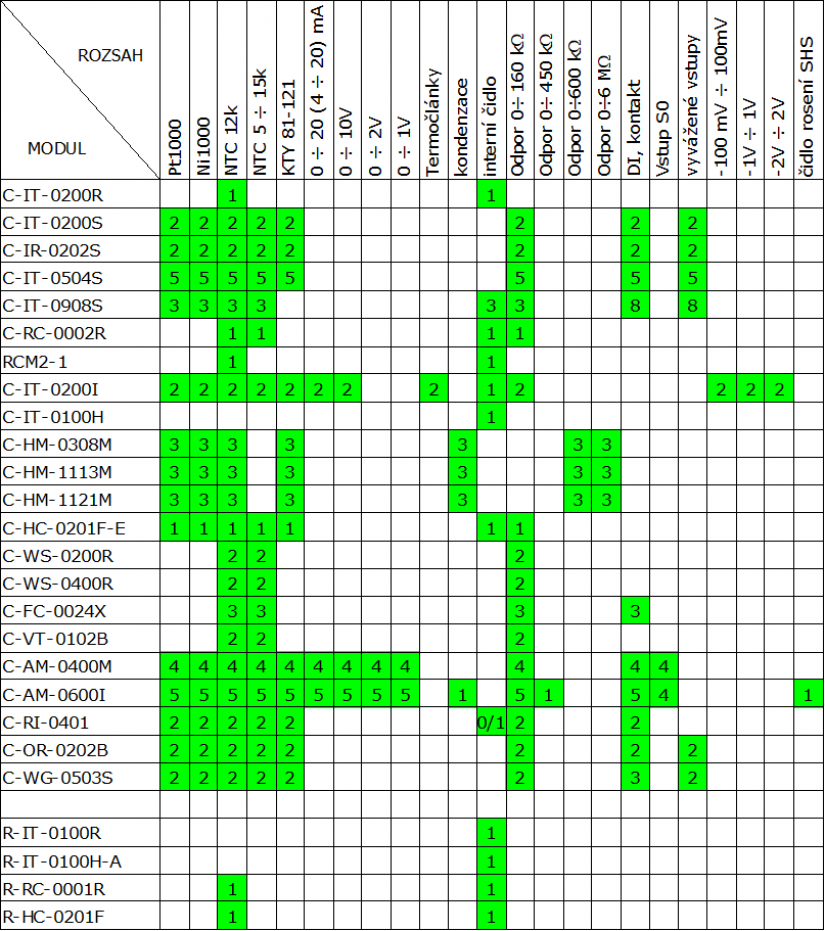

Tab. 8. An overview of the CFox and RFox modules for measuring temperature and analogue values (voltage, current, etc.)

The number in the table box shows, how many inputs of the selected module enable measuring the sensor or the signal in the appropriate column.