To control and regulate heating, cooling and similar systems, various types of valves are used: based on their function there are two-way, three-way and centre valves.

There are valves with only basic function ON/OFF or switching, or there are control valves, mixing and distribution valves.

To control them use the servo-drives, which can be categorized in accordance with the type of control (only ON/OFF or continuous control) into two-point, three-point, analog-controlled and other special variants (e.g. MP-bus controlled).

Two-way valves

A two-way valve is used for opening/closing individual heating branches, etc., or to regulate the flow in the respective branch. Accordingly, a suitable drive should be selected: a two-point or three-point, or analogue-controlled.

Three-way diverter valve

It is used e.g. for switching the heat sources (between the boiler, the heat pump or the solar system), or for switching heating circuits (central heating and heating water), etc.

Mixing function

Mixing diverter valve

The mixing valves are used for mixing two fluids of different temperatures in such a ratio, that the required temperature is reached at the valve outlet. They are divided into three-way diverter valves and centre valves.

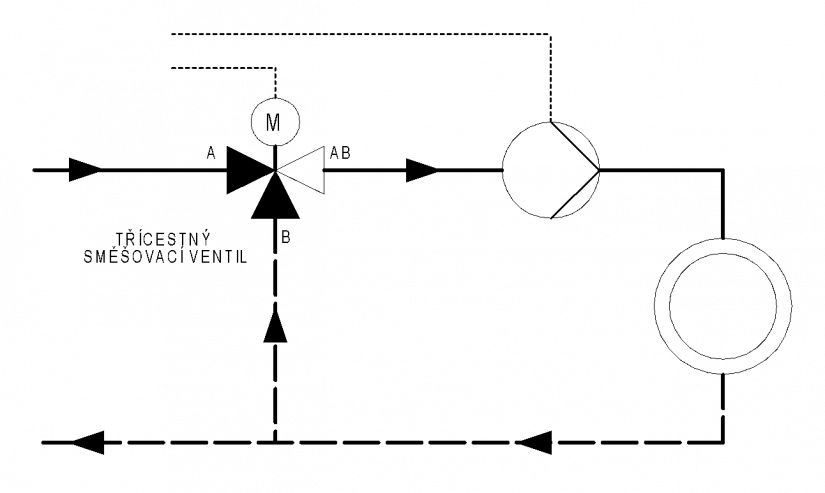

The three-way diverter valves mix water from two inlets into one outlet; by mixing they actually reduce or increase the flow in each inlet. These valves are typically used for mixing the heating water in the

heating circuits (the underfloor or the wall heating, radiators), or for mixing the return branch to solid fuel boilers to prevent the low- temperature corrosion.

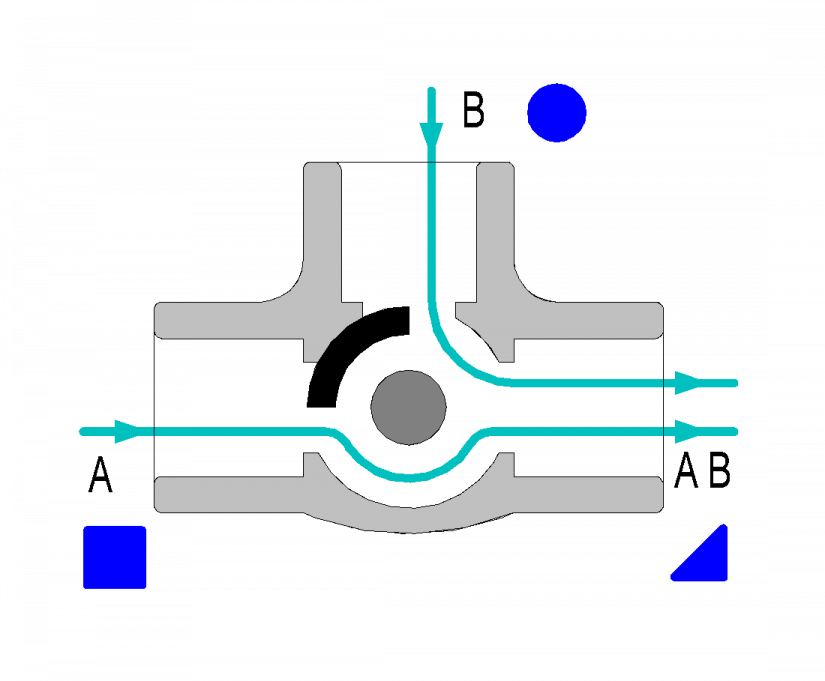

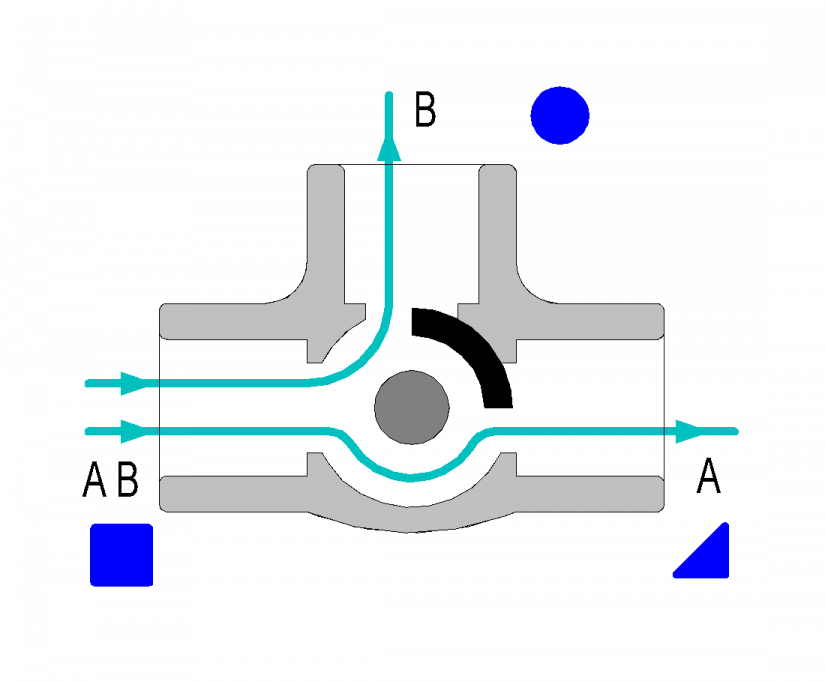

Basic principles of the mixing three-way valve:

The fluid inlets are usually marked with letters A and B.

The common outlet is marked by letters AB.

By moving the black segment (see the figure) the flow smoothly changes from both inlets A and B to the outlet. Usually the control range is 90° from one end (inlet A is open, B is closed) to the second (inlet A is closed, B is open).

In the diagrams the inlets are marked by a full triangle, and the outlets by a blank triangle.

Fig. 1. Mixing heating circuit with a diverter valve

Wherever it is necessary to ensure a constant unhindered flow also at the inlet to the mixing valve, it is necessary to use the centre valve, which provides mixing to the desired temperature, while maintaining the flow on both ends of the valve. A typical example is the mixing of water behind a gas boiler, it which the flow of heating water must be maintained, or mixing the return branch to the solid fuel boilers.

Distributing valve

The distribution function of the valve is similar to mixing. Basically the direction of the flow is reversed.

Two-point control

In the case of On/Off control (in the two-way and three-way diverter valves) you can use the two-point or three-point controlled drives.

A standard method is the two-point control, where the drive is controlled (switched) into the active position by one output. The valve moves to the other end (idle) position after opening the output either by a pull-off spring, or by an actuator powered by permanently connected voltage - see this article. When the two-point-controlled valve is in the idle position, it can be either open or closed, depending on the model.

Three-point control

The mixing valves (the three-way mixing valve, the centre valve, the distribution valve) must be controlled by a drive, which allows setting any working position between the two extreme positions of the valve.

One of the methods is the so-called three-point control, when the drive is controlled via two outputs; there are three states: opening - idle - closing.

The same control method is sometimes also used for two-way control valves, see this article.

The three-point control is identical with standard Venetian blinds motors, and the same principles apply, see this article, which contains further information and requirements for relay outputs, etc.

Analogue control

Drives controlled by 0 to 10 V analogue voltage are also used for continuous valve control. This control allows you to comfortably and conveniently set the exact position of the valve as required by the regulation. The drives are powered either by 230 VAC voltage - then the analogue control in the actuator is terminated individually, or it is powered by standard 24 VAC power supply, and then there is usually one common terminal for the power supply voltage terminal and for the 0 to 10 V analogue input; this should be taken into account when designing the connection. The drive on the heating radiators is powered and controlled in the same way, see this channel.

The bus-type of control, the MP-bus

Proportional control of servo-valves drives and flap drives is also enabled by drives with the MP-Bus interface supplied by Belimo.

For detailed information, see this article.