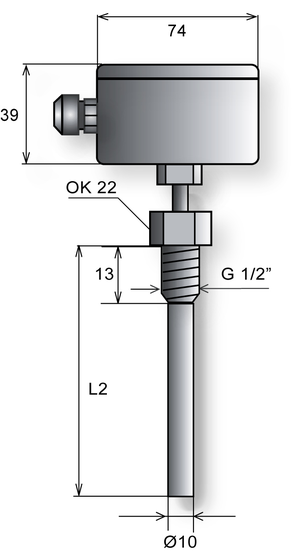

We measure the temperature of the flowing liquid in the pipeline with a temperature sensor with a stem in a stainless steel well installed in the pipeline, we have an attached sensor equipped with a Pt1000 sensor, P13PA-x (x - well length), which we connect to analog system inputs. The terminal block is placed in a plastic head with a terminal block, the metal measuring stem is made of stainless steel class DIN 1.4301. The delivery of the sensor also includes a stainless steel well with a G1/2 “thread. The standard design of the module is designed for a maximum temperature of 150 ºC, the stem is about 20 mm longer than the well. Sensors with an extended stem of 60 mm can also be used for temperatures up to 250 ºC (column "Version up to 250 °C" in the table with order numbers). The sensors are used in normal environments where they are not exposed to aggressive chemicals.

| Measuring range | -30 ÷ +150 ºC (extended -30 ÷ +250 ºC) |

| Accuracy class | B according to IEC 751 |

| Insulation resistance | > 100 MΩ at 25 ºC (500 VDC) |

| Degree of protection | IP 65 (ČSN EN 60529) |

| Relative humidity | < 95 % |

| Ambient temperature | -30 ÷ +80 ºC |

| Stem | stainless steel, DIN 1.4301, Ø = 6 mm, stem lengthL1: see table |

| Valve head | material polycarbonate, color gray

dimensions: 74x66x39 mm |

| Gland | PG9, cable diameter 4 ÷ 8 mm |

| Terminal blocks | conductor cross section 0,35 ÷ 2,5 mm² |

| L2 (mm) | Order number | Order number |

| Version up to 150 ° C | Version up to 250° C | |

| 100 | P13PA150-100 | P13PA250-100 |

| 160 | P13PA150-160 | P13PA250-160 |

| 220 | P13PA150-220 | P13PA250-220 |

| 280 | P13PA150-280 | P13PA250-280 |

| 340 | P13PA150-340 | P13PA250-340 |