Dewing can be prevented using a special SHS sensor with the resistance characteristic and sensitivity to high air humidity. Typical applications include cooling ceilings, control panel cabinets and similar devices, where dewing e.g. on the walls must be prevented.

The sensor can withstand short periods of up to 100% humidity, but it must not be exposed to continuous condensation.

The sensor should be fixed with an adjustable strap on the feed pipe (the coldest part of the system), or it can be screwed onto the monitored surface. The contact surfaces between the sensor and its seating can best be coated with some thermally conductive paste. The sensor should be protected against damage and getting dirty (by colouring, etc.).

There must be a small hole in the plaster under the sensor, so that air could penetrate from the room to the sensor. Only then the sensor can correctly measure the humidity of air in the place where the system pipe is located.

|

The range of relative humidity (RH) |

0 to 100 % |

|

The range of temperatures |

0 to 60 °C |

|

Dimensions (the metal base of the sensor) |

20 x 12x 0.6 mm |

|

Mounting hole |

Ø 3.2 mm |

|

Impedance at RH < 75% |

< 20 kΩ |

|

Impedance at RH < 93% |

< 100 kΩ |

|

Impedance at RH > 97% |

> 150 kΩ |

|

The reaction time due to the humidity changes from 75 to 99.9% |

around 60 s |

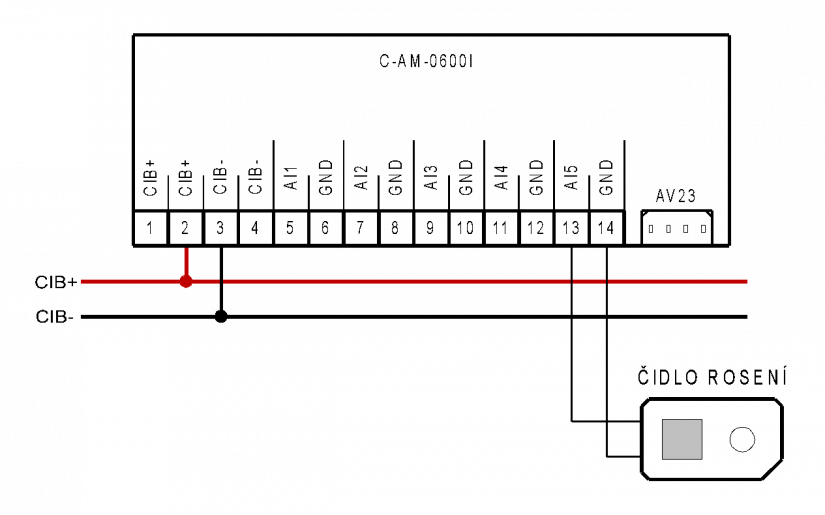

Fig. 1. An example of wiring the SHS dew sensor to the C-AM-0600I module

Notes:

-

The SHS sensor can only be connected to the AI5 input.

-

The supply cable can be extended up to approx. 30 m. You should use a shielded cable, e.g. the SYKFY 2x2x0.5, or J-Y(St)Y 1x2x0.6.

-

When the sensor is being mounted, care should be taken to maintain quality conductive connection with the monitored surface, and to avoid damaging the active surface of the sensor.